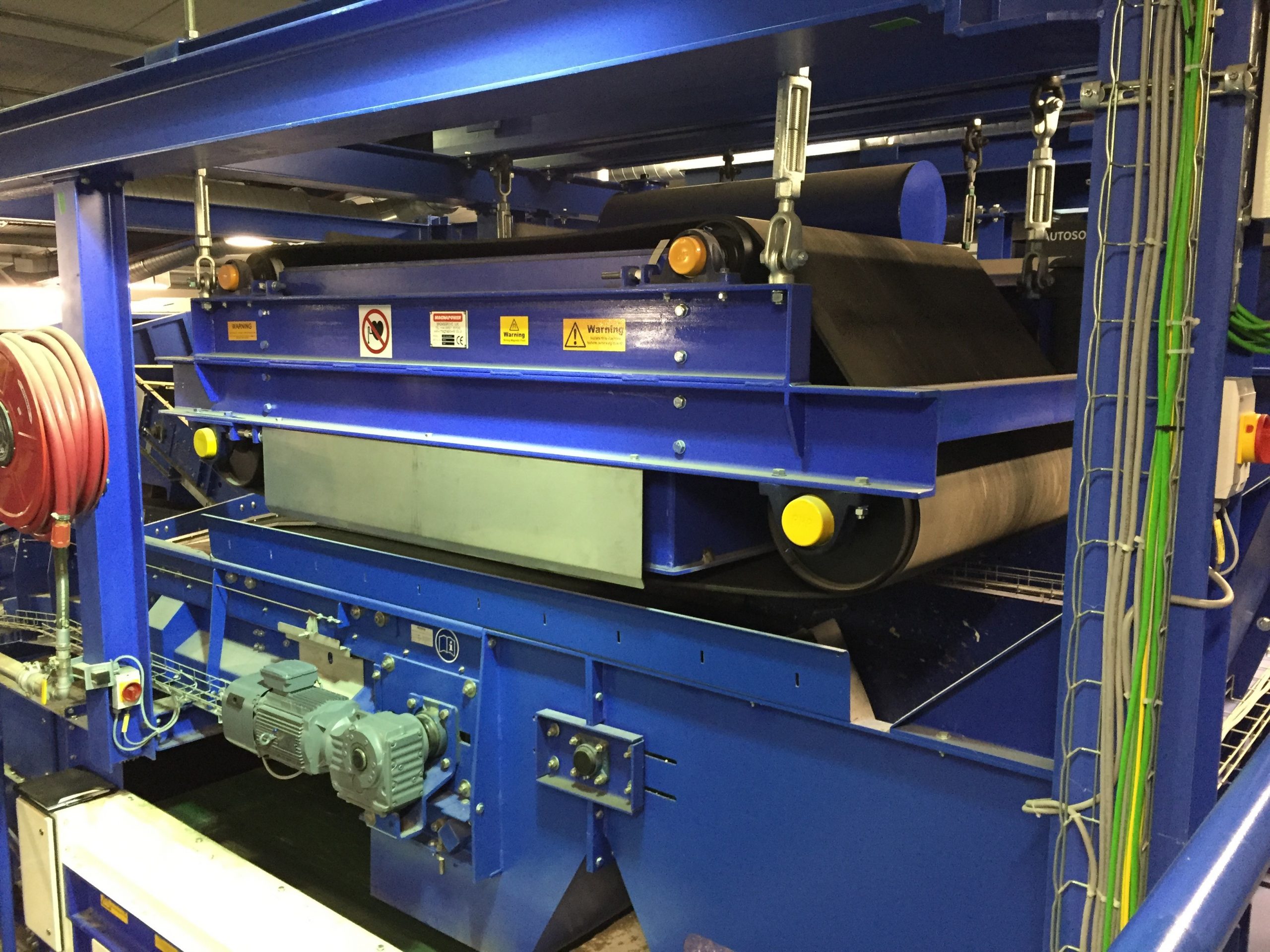

Magnapower manufacture a full range of Electro Magnet Overband separators. They provide excellent levels of ferrous separation and are used in virtually all material handling and recycling industries.

They have a high powered deep magnetic field and are built using a heavy-duty construction with wear resistant parts throughout.

Magnapower’s fast response, expertise and service is there for you.

The electro magnet overband can be positioned either as a crossbelt or in-line separators.

Operation

Material on the conveyor passes underneath the overband magnet. Ferrous metal is attracted to its surface allowing the ‘cleaned’ product to continue along the conveyor as normal.

The continuously moving belt of the overband carries the ferrous metal over the side or past the conveyor where it drops out of the magnetic field.

The material under the conveyor needs to be from non-magnetic material to prevent magnetisation.

The main reasons for using an electromagnet system over a permanent would be either for a high working gap (usually above 400mm) or if the magnet needs to be switched off occasionally.

Most electromagnet systems use an aluminium conductor and can be either oil cooled (to reduce quantity of aluminium in windings) or air cooled.

The electromagnet requires a transformer rectifier supplied with it to provide the DC supply to the magnet coil. Transformers should be located close to the overband magnet to limit the length of DC supply cable.

Please contact us for more details about the best position for an overband magnet and also the most suitable magnet system for your plant.