The Magnapower range of magnetic separators provide excellent levels of separation for applications in the food industry.

These are designed to prevent ferrous metal contamination in food products and the ongoing problems that this otherwise will cause.

Magnapower fast response, expertise and service is there for you.

Magnet Systems

Standard Strength Ferrite Magnets – for the removal of general tramp metal such as nails and screws

High Intensity Rare Earth Magnets – for the removal of tramp metal and weakly magnetic pieces such as fine ferrous particles and metal with non-magnetic attachments.

Please send us details of your material so we can make our recommendations to you.

- Higher levels of cleaner metals

- Heavy duty parts and construction to reduce any maintenance requirements

- Magnetic force focused into product only where it is needed

- Excellent back up and service

Our commitment is to provide separators which are the leading performers in the industry.

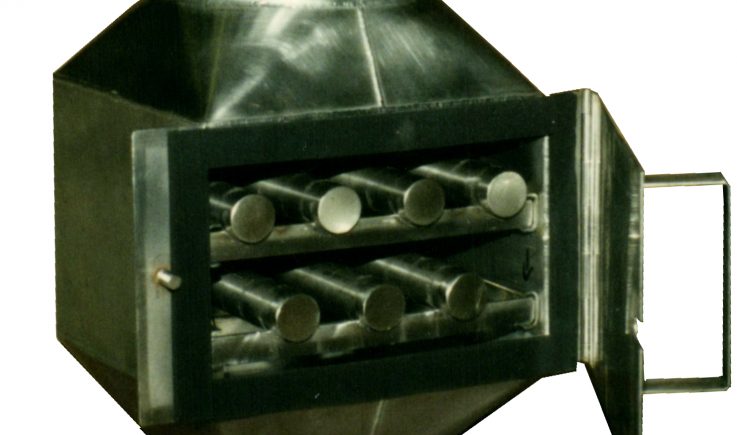

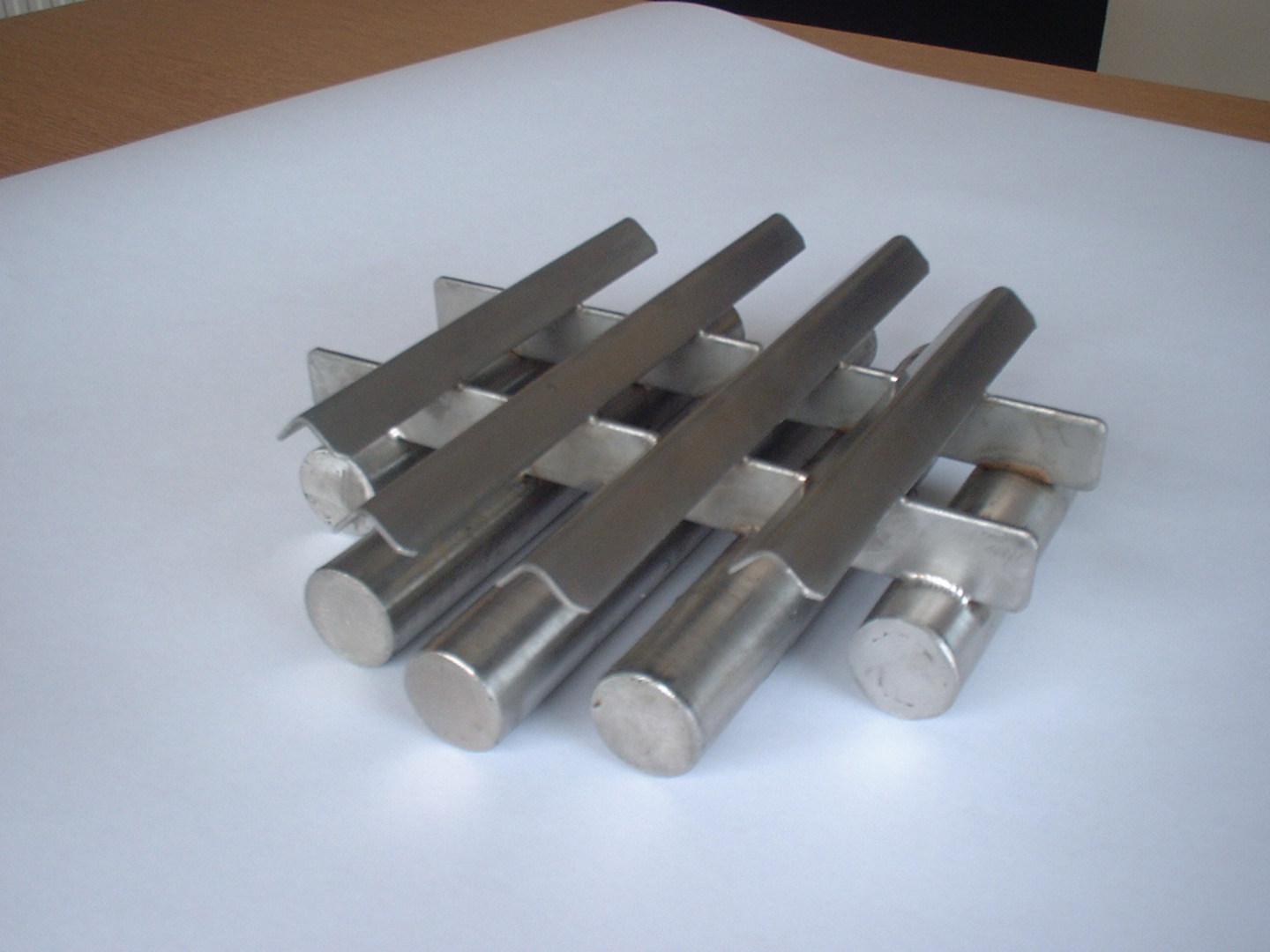

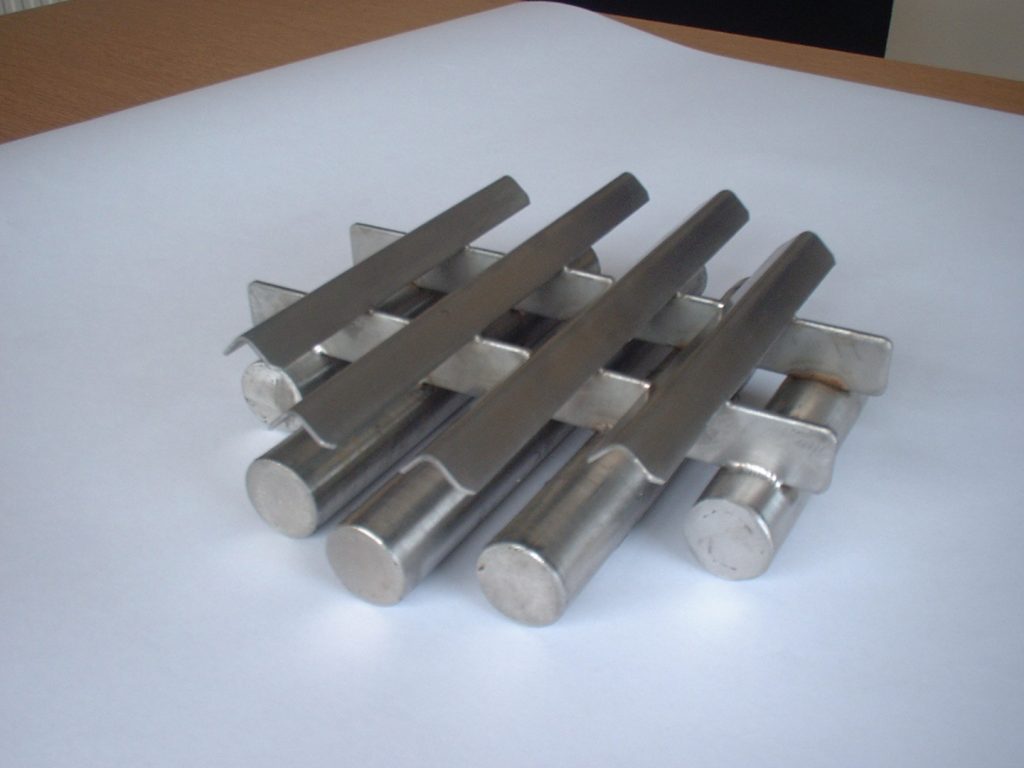

MAGNAGRID

The MAGNAGRID is designed for easy installation into hoppers, chutes, ducts, bins etc. Material passes over the permanent magnetic tubes and ferrous contaminants are held firmly in place allowing the clean material to flow freely past the grid. Maintenance simply requires periodic removal of the grid to wipe it clean before replacing it.

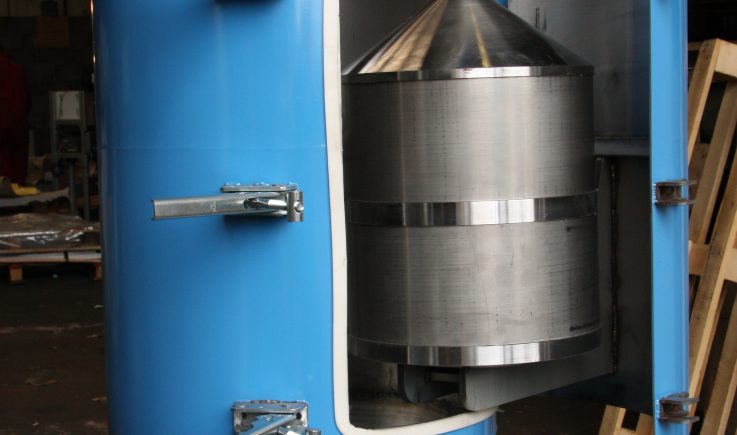

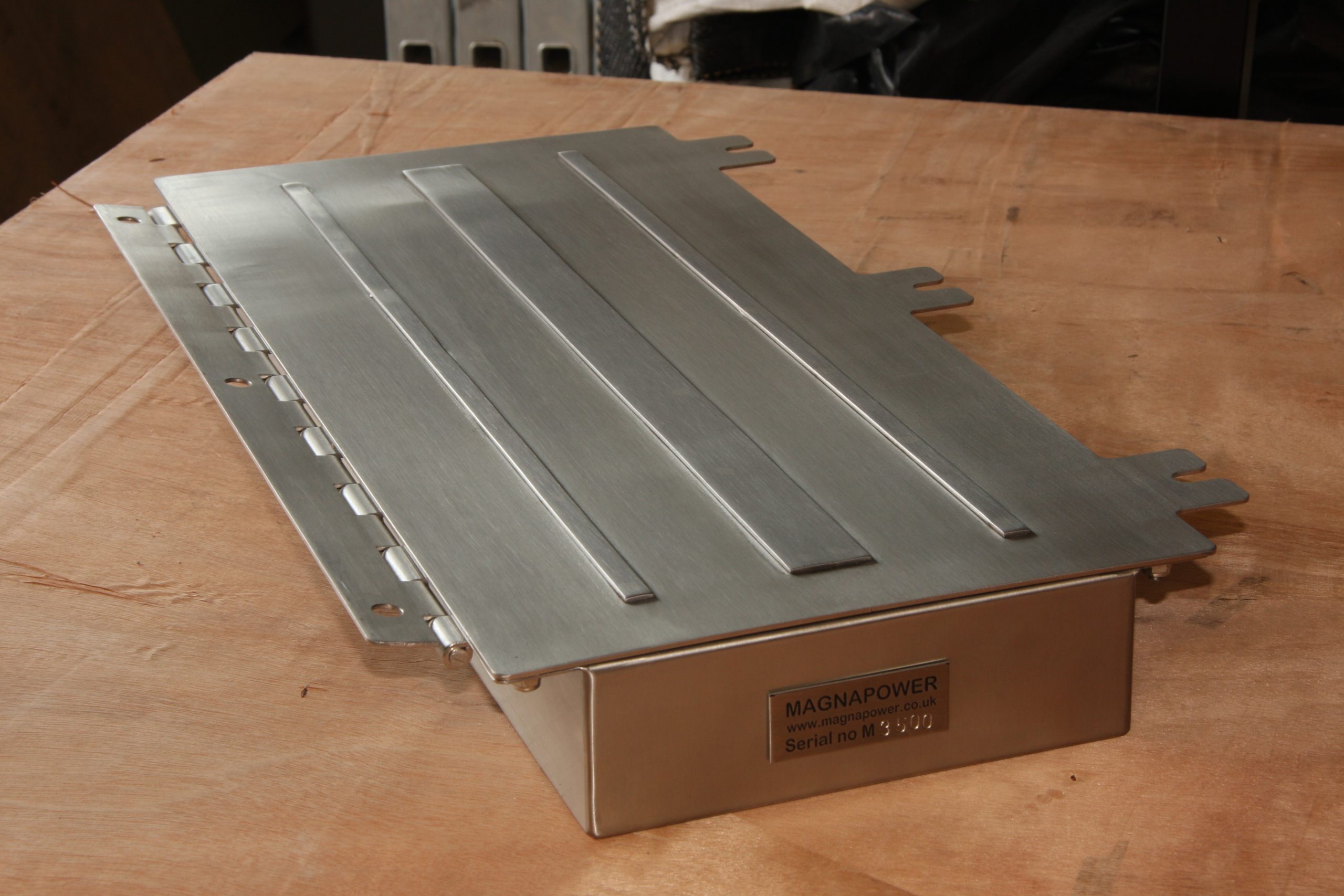

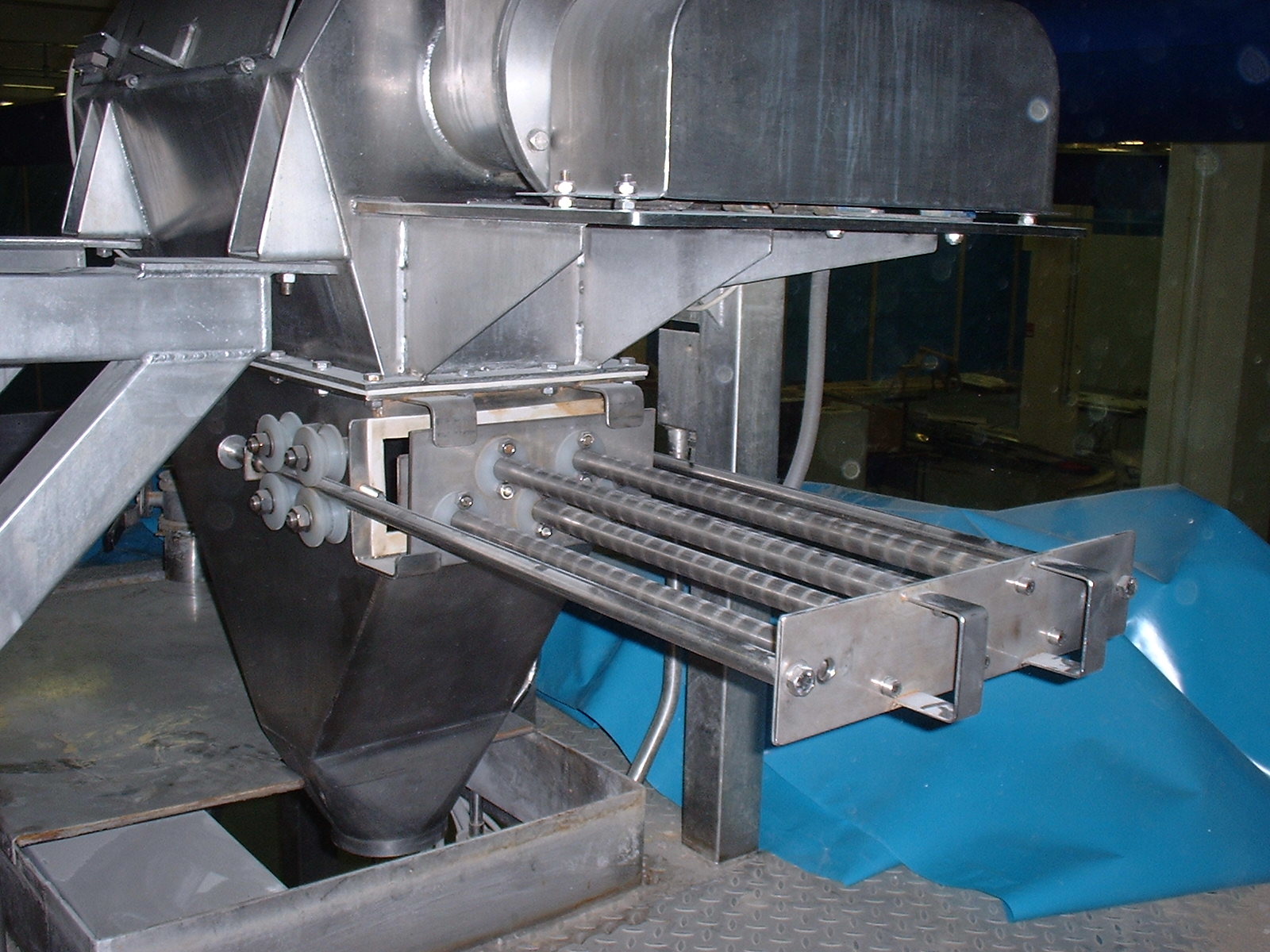

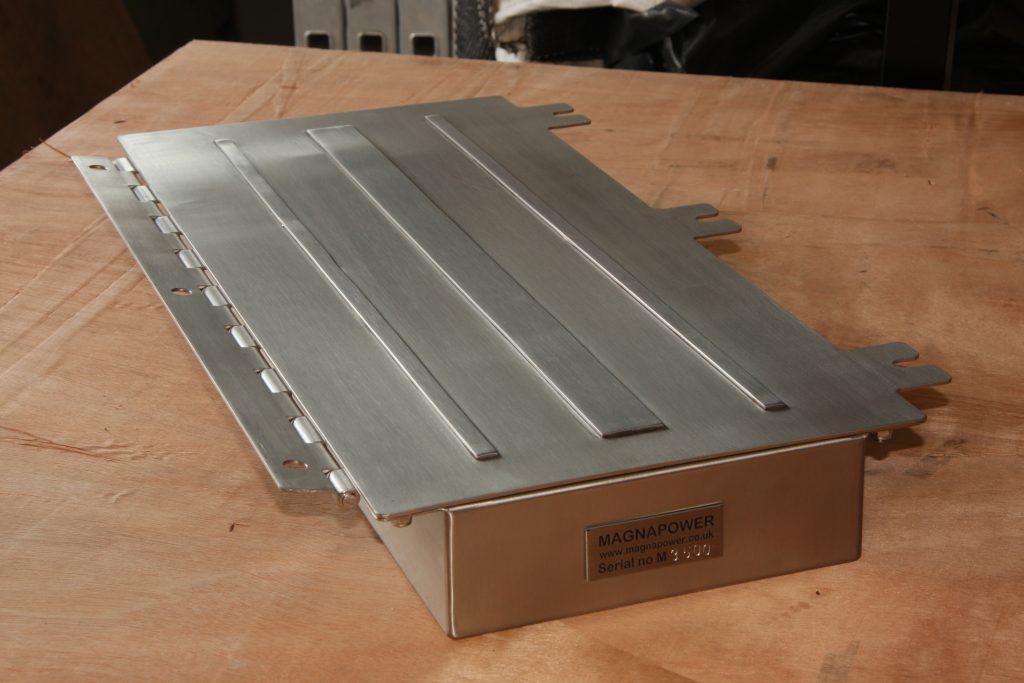

MAGNADRAWER

The MAGNADRAWER can fit into a working system and can be easily cleaned where a Magnagrid would be inaccessible. The magnetic grid within the drawer removes ferrous contamination in the same way as the Magnagrid. To clean the contaminants from the grid the drawer is opened, the grid wiped clean and then the drawer closed.

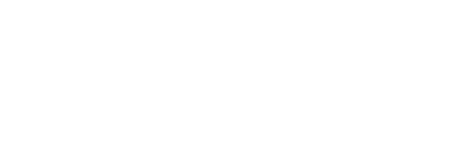

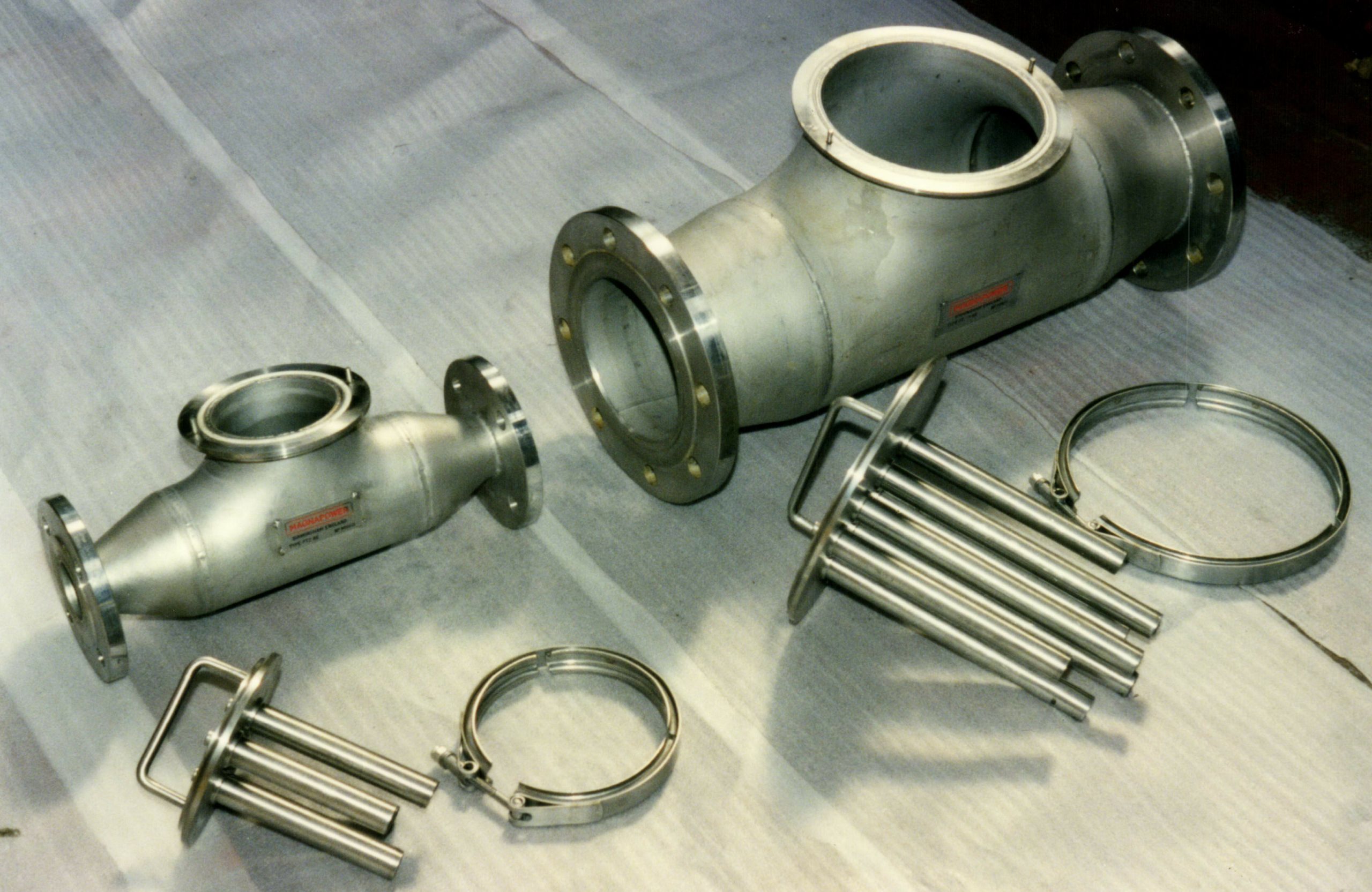

MAGNACONE

The MAGNACONE is designed for installation into gravity fed or pneumatic pipeline systems. Material passes into the Magnacone chamber and with the combination of cone and diverter, material is directed over the high intensity magnetic poles. This allows the clean product to flow freely from the chamber. The Magnacone is attached to the chamber door which is easily opened with quick release catches. This enables simple cleaning of the magnet thus minimising any interruptions to production.

MAGNAPLATE

The MAGNAPLATE can be positioned either above a chute/conveyor or within a sloping chute. Ferrous contamination is attracted to the face of the magnet and held in position allowing clean material to flow away from the plate. Maintenance of the Magnaplate above a chute/conveyor requires the wiping of the face of the magnet clean (an optional cleaning tray is available). When positioning below a chute, the Magnaplate is hinged so that the working face can be exposed for cleaning.

FERROUS TRAP

The MAGNAPOWER FERROUS TRAP provides an efficient method of removing ferrous contaminants from liquid products. Liquid passing through the Ferrous Trap reaches a high intensity magnetic field. Any ferrous particles are held in position allowing the clean product to flow freely from the chamber. The magnetic field is provided by a series of high intensity tube magnets. These are fitted to the lid which is easily opened with the quick release vee-clamp. The magnets can then be wiped clean of contaminants and replaced in the chamber.

All units are available with either standard strength or high intensity rare earth (neodymium) permanent magnet systems.