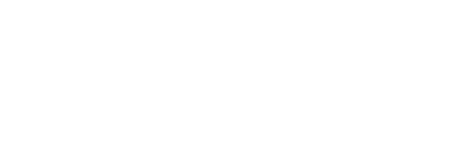

The Magnapower range of In-line Overband Magnets provide excellent levels of ferrous separation. They have the significant advantage of improved ferrous separation and reduced belt wear.

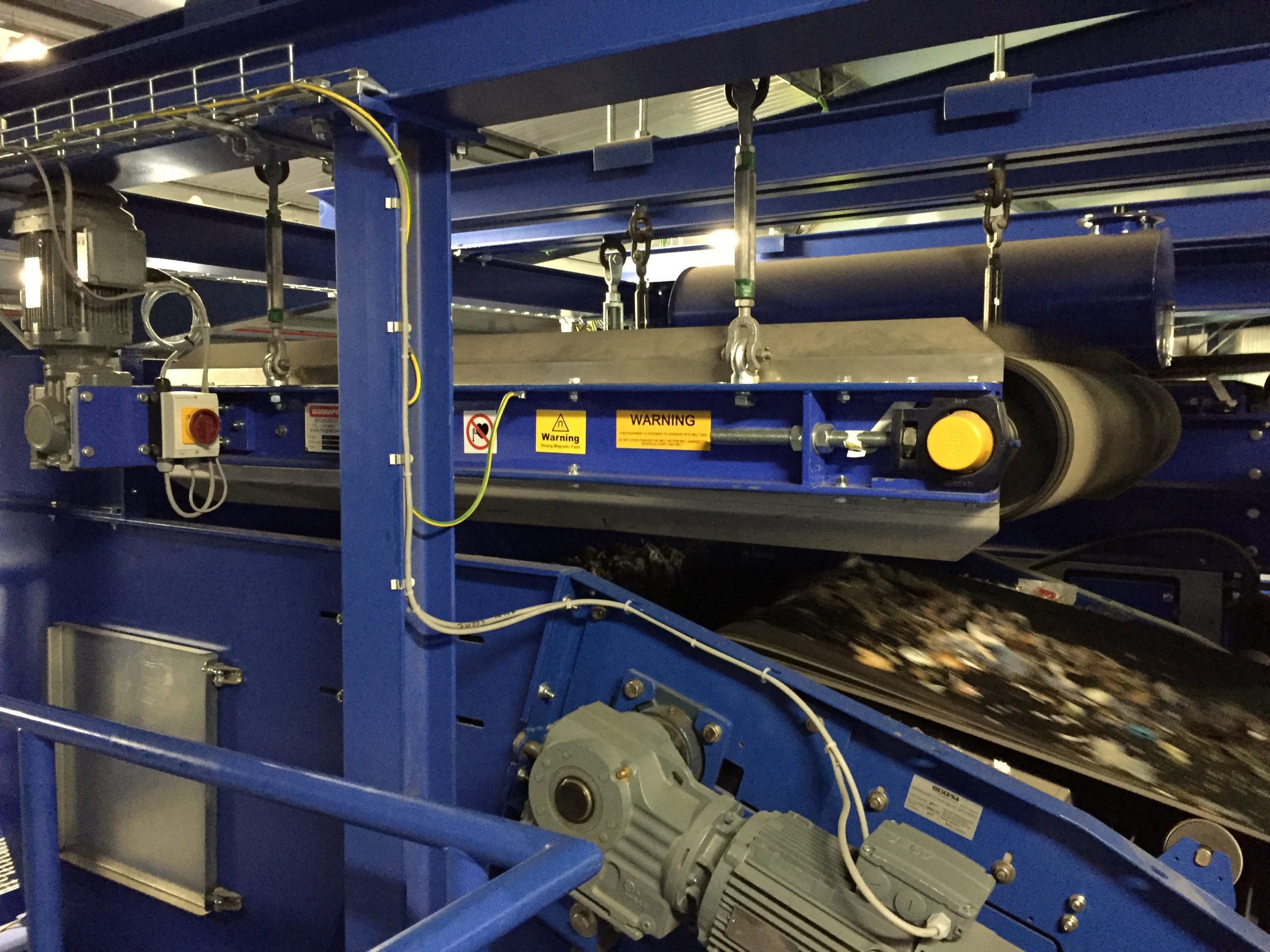

They have a high powered deep magnetic field and are built using a heavy-duty construction with wear resistant parts throughout.

Magnapower’s fast response, expertise and service is there for you.

Operation

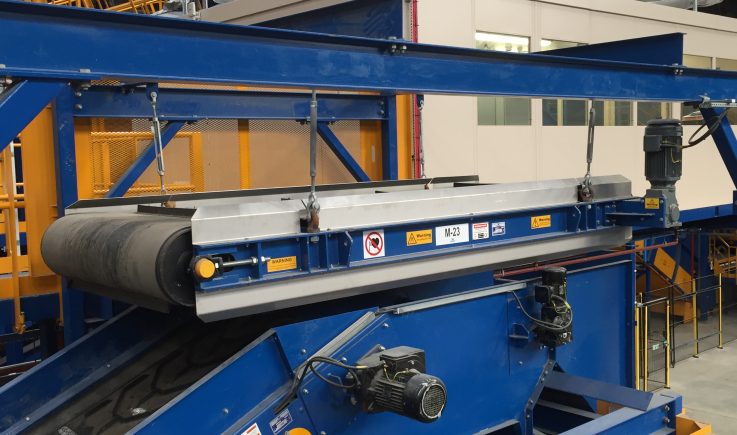

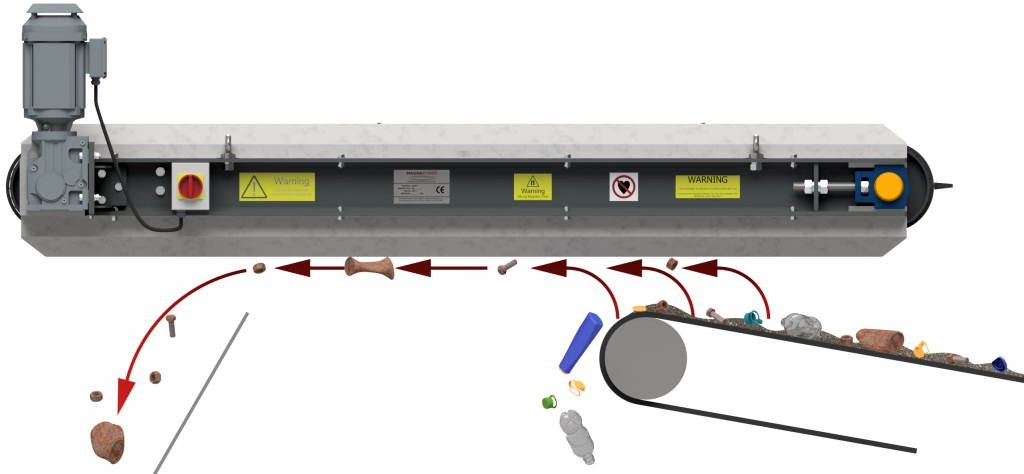

Material on the conveyor passes underneath the overband magnet. Ferrous metal is attracted to its surface allowing the ‘cleaned’ product drop away from the conveyor as normal.

The continuously moving belt of the overband carries the ferrous metal further forward where it then drops out of the magnetic field.

The material under the overband (e.g. the conveyor head pulley or vibratory feeder) needs to be from non-magnetic material to prevent magnetisation.

There are a number of advantages to installing the overband in the in-line rather than crossbelt position such as:

- Increased ferrous extraction – due to it being less entrapped in the product as it falls from the conveyor belt

- Less contamination in the ferrous – due to it not dragging the ferrous across the product which can trap product in with it

- Extended length magnet system – to carry the ferrous a greater distance away from the product

- Alternating pole magnet extension – to allow more release of non-magnetic items from the ferrous

- Reduced belt wear – due to ferrous not needing to change direction which can otherwise cause more trapping of longer / sharper ferrous items

- Reduced working gap – as magnet does not need to clear side frames or trough of conveyor

Please contact us for more details about the best position for an overband magnet in your plant.